CNC Laser Cutting Machine

Capacity: 18 PPM (Pieces Per Minute)

Utilizes laser technology to cut metal sheets according to production blueprints, precisely shaping the required product components.

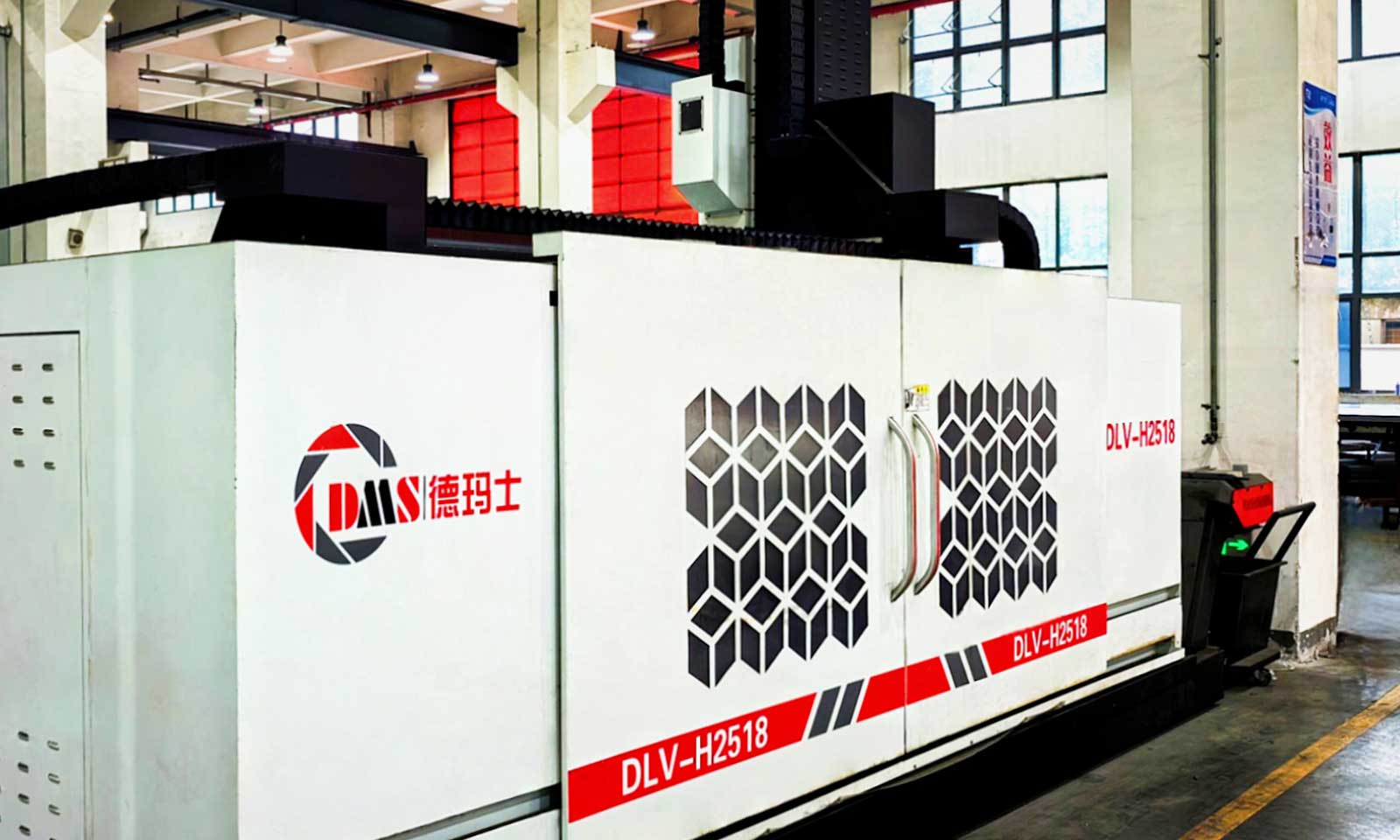

CNC Machining Center

Capacity: 15 PPM

Performs high-precision cutting, punching, pressing, and milling on metal sheets to meet design specifications.

Bending Equipment

Capacity: 10 PPM

Processes metal sheets through bending operations based on product specifications to form required structures.

Riveting Equipment

Capacity: 15 PPM

Connects sheet metal components via automated riveting for structural assembly.

Welding Section

Capacity: 1 PPM

Welds the main body of the sheet metal enclosures to form a robust frame.

Sheet Metal Surface Grinding

Capacity: 8 PPM

Polishes the external surfaces of sheet metal parts to enhance flatness and finish quality.

Powder Coating Line

Capacity: 200 PPM

Applies protective and decorative coatings to metal surfaces via automated spraying systems.

Final Assembly – Sheet Metal Enclosure

Capacity: 5 PPM

Assembles and integrates coated metal components into completed outer enclosures.

Final Assembly – Sheet Metal Enclosure

Capacity: 5 PPM

Assembles and integrates coated metal components into completed outer enclosures.

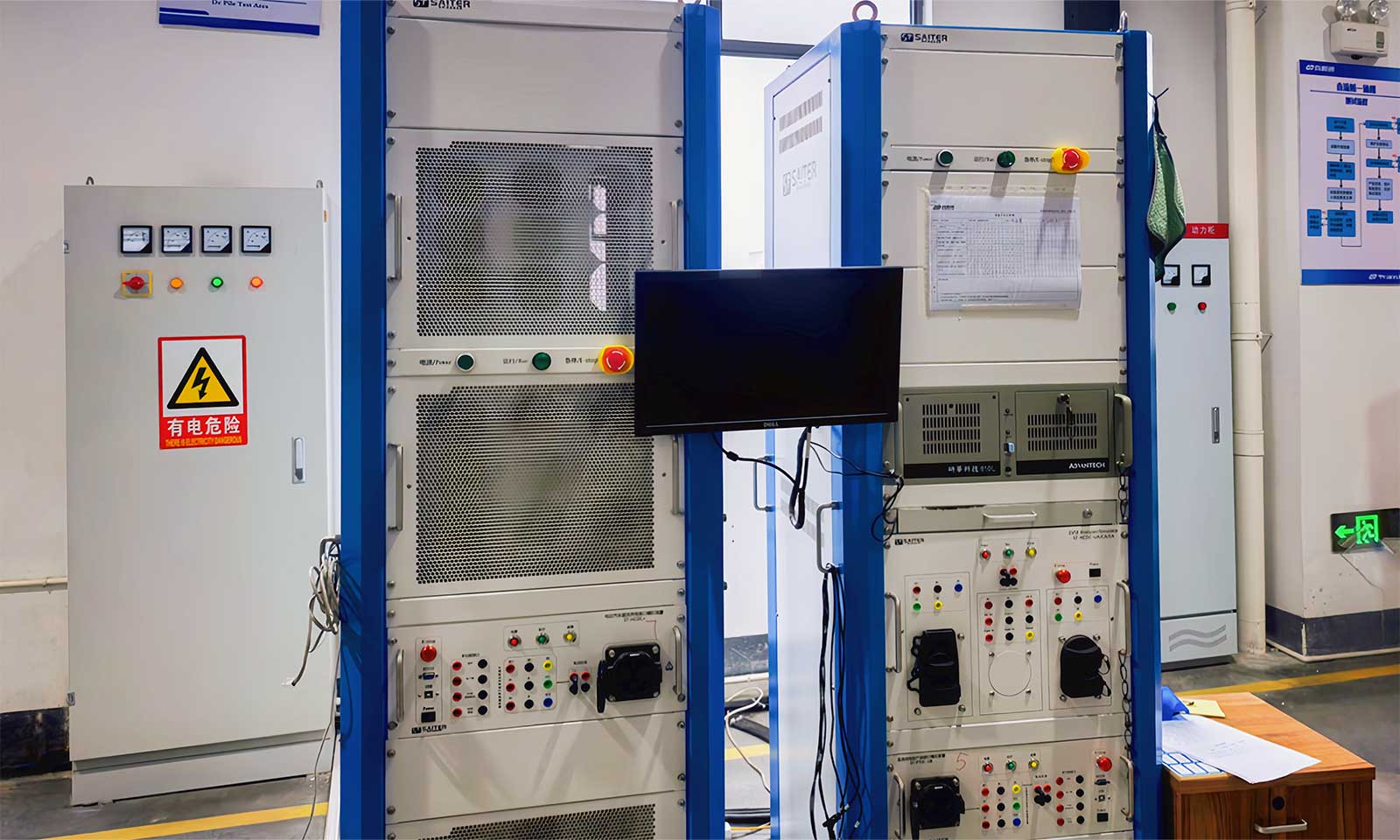

Charger Cabinet EOL (End-of-Line) Testing System

Tests product safety compliance, protective functions, control guidance, and input/output electrical parameters to ensure full functionality.

Charger Aging System

Conducts prolonged testing to simulate real-world operating

conditions,ensuring durability and long-term reliability.