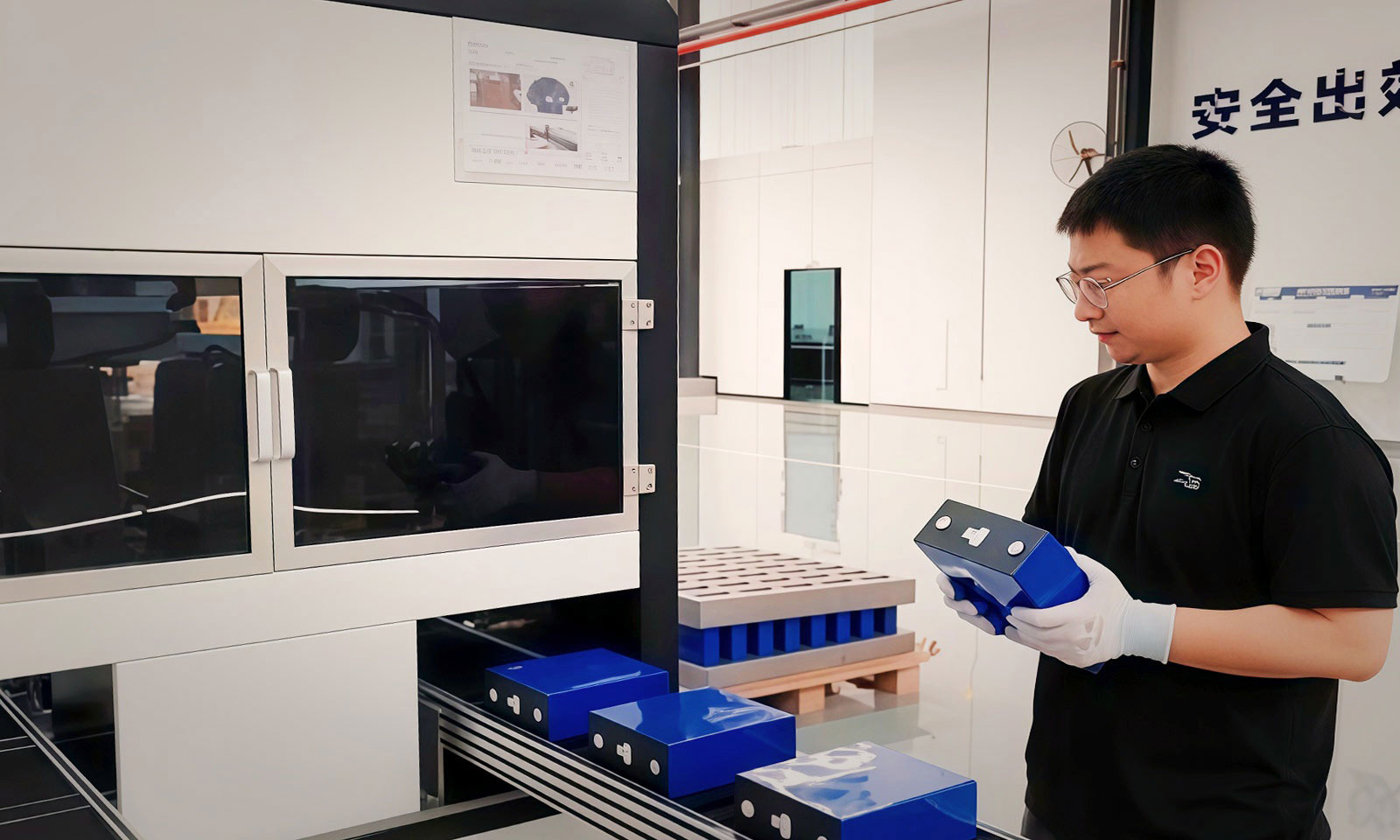

Cell Loading Station

Capacity: 12 PPM

Battery cells are placed in belt line slots with uniform polarity orientation.

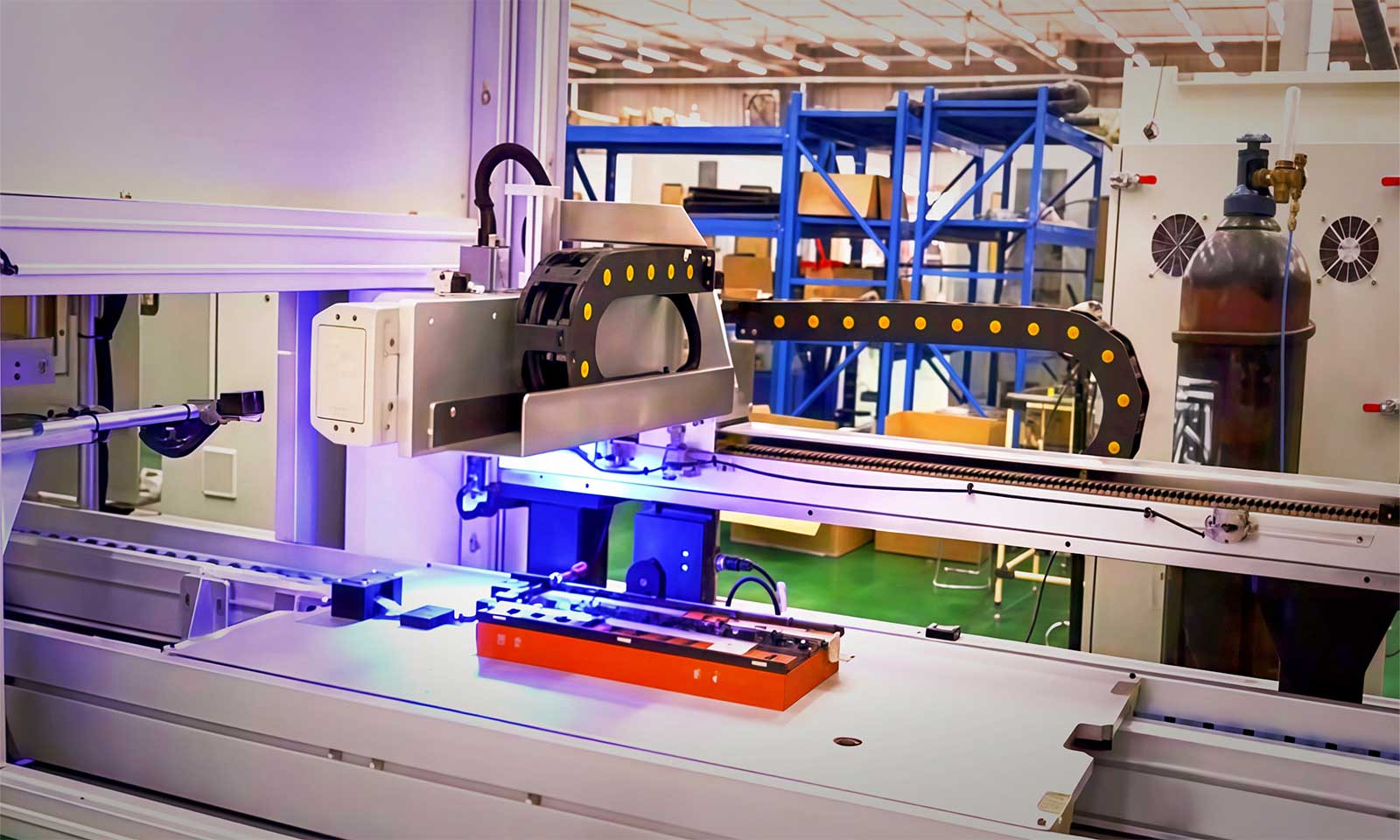

Cell OCV Testing

Capacity: 13 PPM

The 3563 tester measures internal resistance and voltage, with real-time MES upload.

Module Stacking

Capacity: 10 PPM

After PET foam is attached, cells and end plates are arranged on the jig according to polarity.

Module Compression

Capacity: 12 PPM

Modules are compressed with top and bottom steel belts under preset electric cylinder pressure and displacement.

Busbar Positioning (CCD)

Capacity: 10 PPM

CCD cameras capture busbar images and define marking points.

Busbar Cleaning

Capacity: 12 PPM

A high-power 80W laser removes oxidation and impurities from the busbar surface.

CCS & Terminal Installation

Capacity: 12 PPM

Main positive/negative terminals and CCS components are installed.

CCS Laser Welding

Capacity: 12 PPM

A 4000W fiber laser welds CCS aluminum bars to battery terminals.

Module Insulation & Withstand Voltage Test

Capacity: 12 PPM

Safety tester measures leakage current and insulation resistance between terminals and end plates.

Module Offline Transfer

Capacity: 14 PPM

Qualified modules are transferred by KBK crane to the pallet for storage.

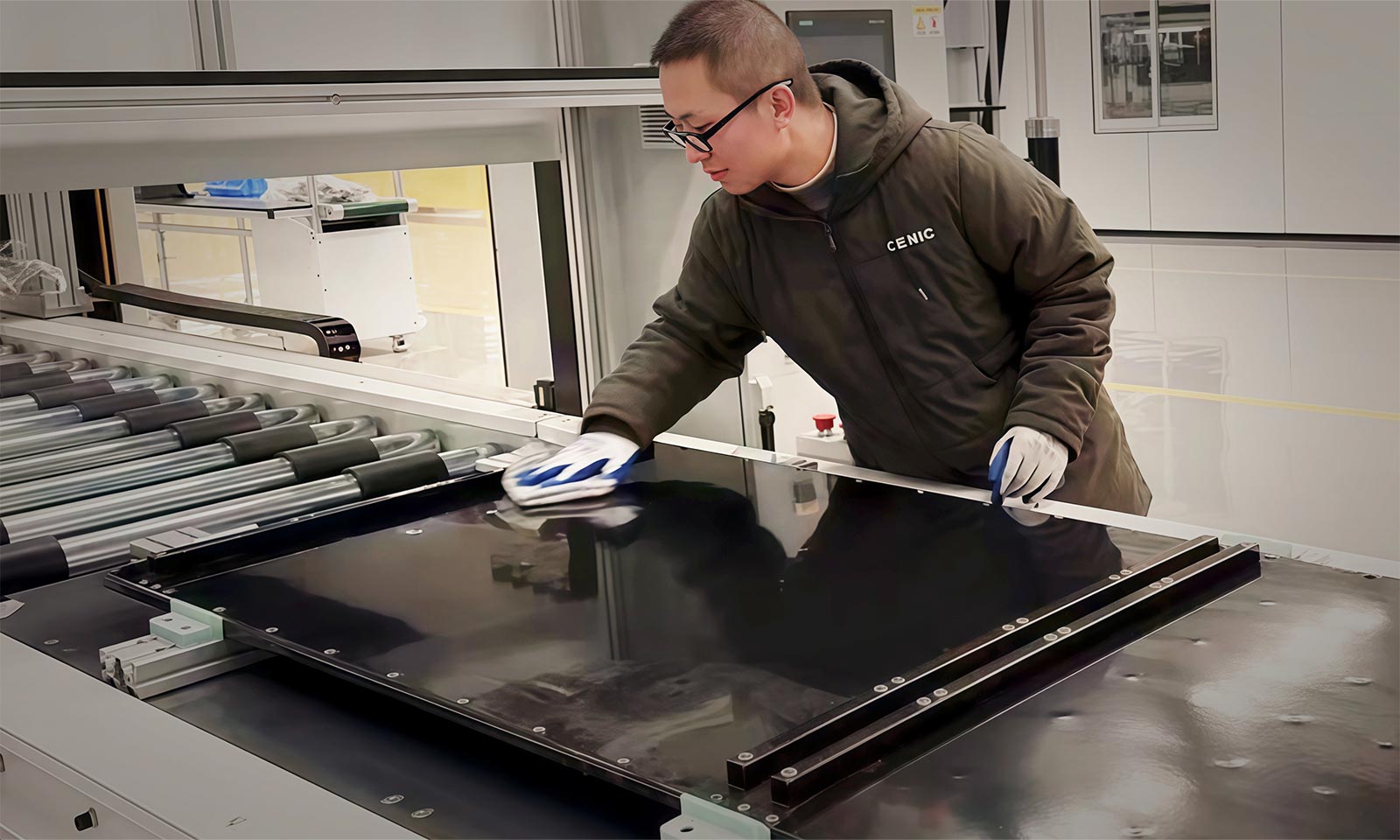

Cooling Plate Loading, Cleaning, and Sealing Strip Application

Capacity: 10 PPM

An articulated arm hoists the cooling plate onto the production line, where it undergoes surface cleaning and the application of sealing rings and rubber strips.

Cooling Plate Airtightness Test

Capacity: 12 PPM

Airtightness testers ensure proper sealing performance of cooling plates.

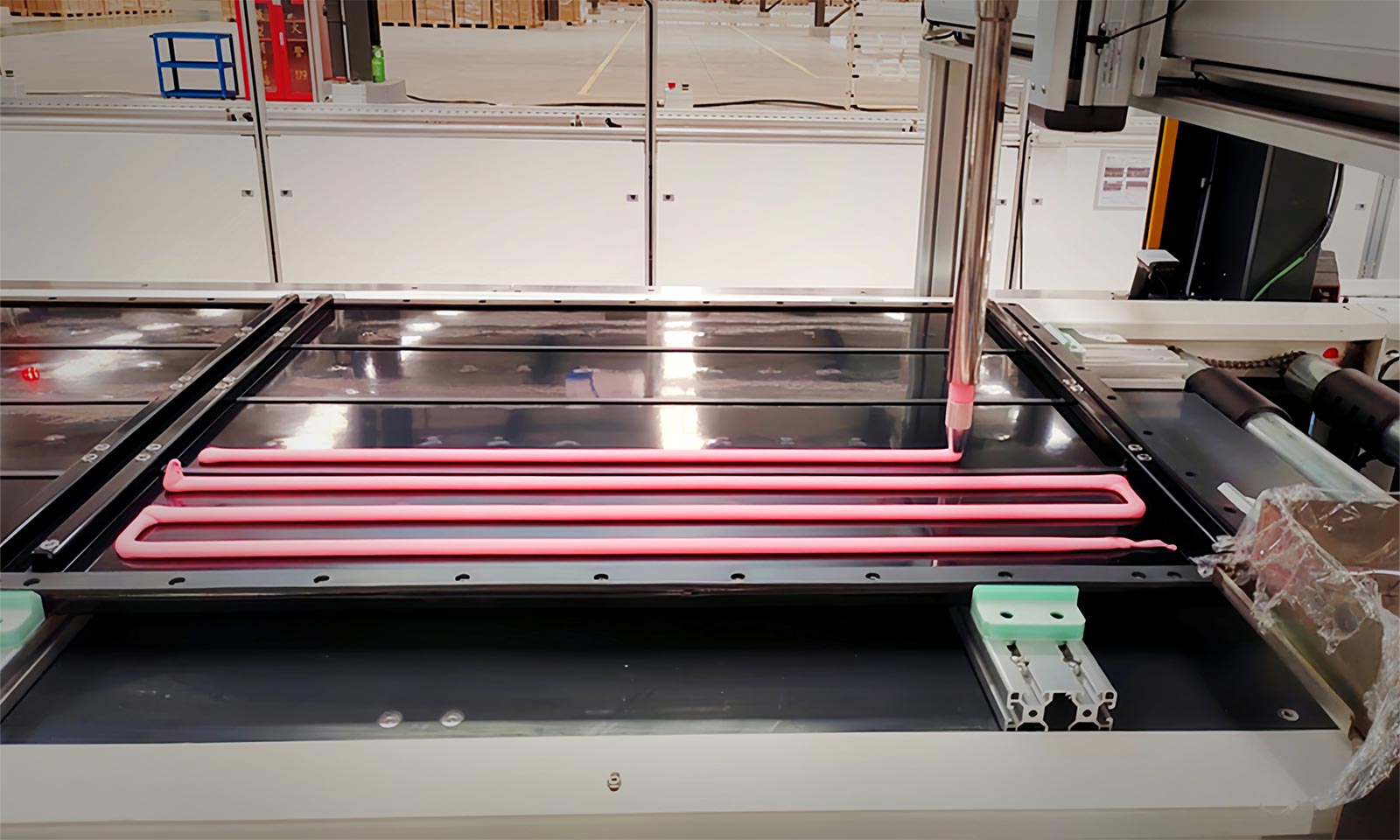

Thermal Compound Dispensing

Capacity: 10 PPM

A dispensing machine applies thermal conductive paste onto the cooling plate following a programmed path.

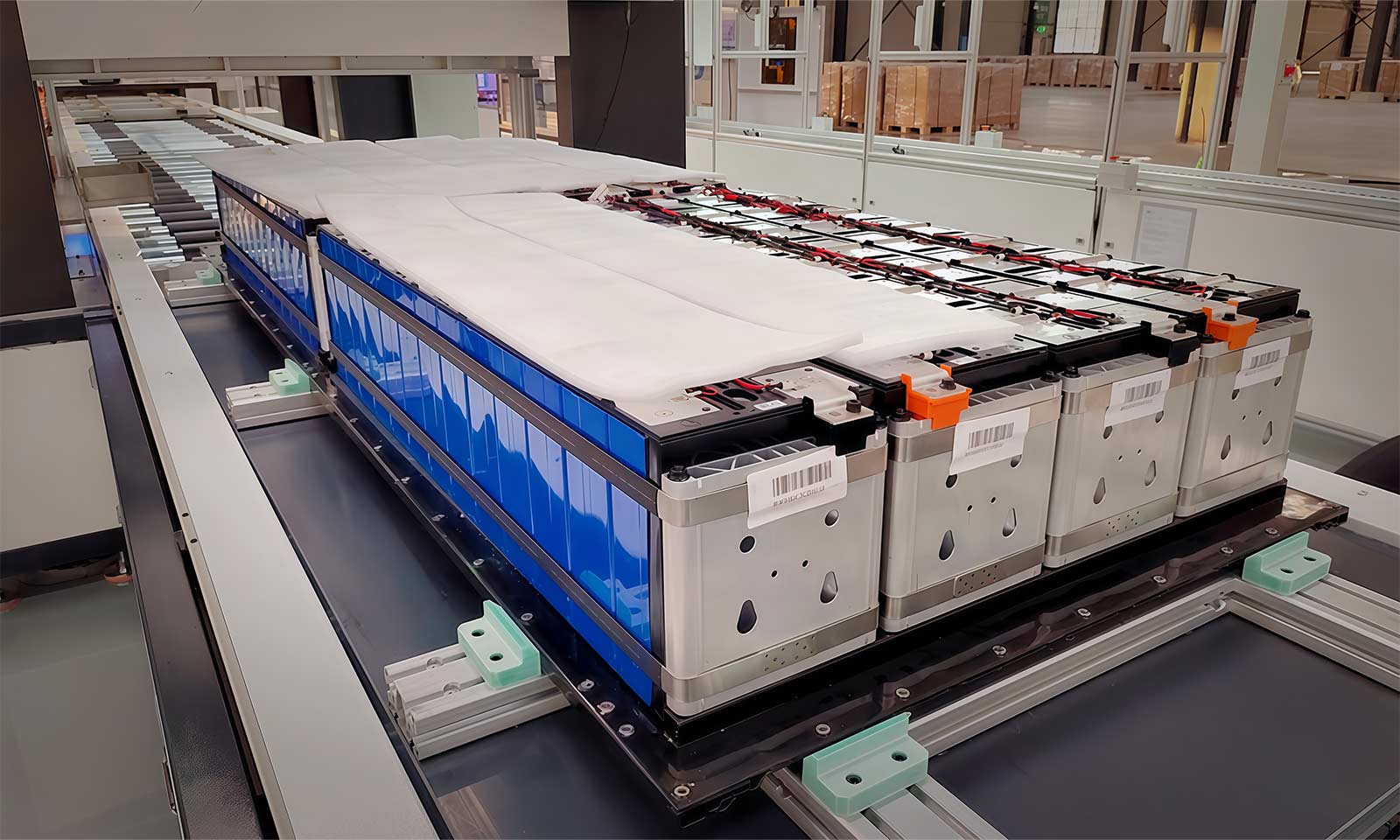

Module Placement onto Cooling Plate

Capacity: 10 PPM

The KBK crane lifts the battery module and positions it onto the cooling plate. The module is arranged according to polarity and securely fastened with screws.

Installation of Active Bracket Assembly

Capacity: 11 PPM

The active bracket assembly—comprising busbars, input/output interfaces, fire protection modules, signal connections, and control units—is mounted onto the front end of the cooling plate.

Installation of Sampling Harness

Capacity: 10 PPM

Each module is connected to the BMU (Battery Management Unit) via a sampling harness to monitor cell voltage and temperature at designated sensing points.

Copper Bar Installation

Capacity: 11 PPM

Modules are electrically connected via copper bars and secured with screws.

End-of-Line Testing (EOL)

Capacity: 10 PPM

Comprehensive testing of insulation resistance, leakage current, cell voltage, and temperature data.

Top Cover & Service Panel Installation

Capacity: 10 PPM

Top covers and service panels are mounted and locked with screws.

Final Pack Airtightness Test

Capacity: 12 PPM

Airtightness testing ensures the complete battery pack meets sealing standards.

Pull Test

Pull tester measures lateral tensile strength of welded terminals.

Weld Metallography Inspection

Cross-sections of welded areas are analyzed using CCD imaging for weld pool inspection.

Charge & Discharge Efficiency Test

Battery packs are tested for charge/discharge efficiency and performance.